You might struggle to choose gifts when you do not know the recipients’ tastes.

There is a new simple solution: CHOOSE KNIT. Since 2013, CHOOSE KNIT has produced personally customized knitted gifts with entirely new system. It involves customers in design process with an order book which they can pick their favorite colors and designs to order.

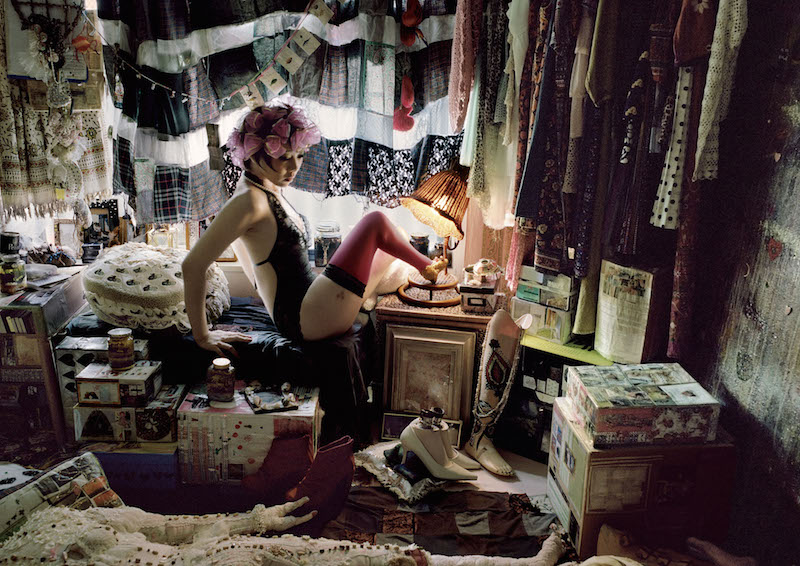

(Photography: Courtesy of CHOOSE KNIT)

Oshima Meriyasu in Sano city, Tochigi prefecture is in charge of knitting the ordered products. The CEO of this factory is the father of the founder of CHOOSE KNIT, Hiroyuki Oshima.

Oshima runs a design office and makes his living by designing websites and printed products. "I had no interest in succeeding my father's factory," he says. However, CHOOSE KNIT was made with the intention of supporting his father’s factory.

I interviewed the father and son who work independently, while aiming for a future together.

(Left) Hiroyuki OSHIMA Creative director of CHOOSE KNIT, CEO of design company genre inc.

(Right)Father, Keiji Oshima CEO of knitting factory Oshima Meriyasu.

――CHOOSE KNIT would never have been born without Oshima Meriyasu, the family factory of Oshima. First of all, what kind of factory is it?

Keiji (father): It is a weft knitting factory founded by my father in 1963. I myself like creating things, and I find knitting interesting because you can knit in numerous ways with the same yarn. Our house was located right beside the factory, so I could pick up the techniques without being taught by my father.

Hiroyuki: However, I didn’t want to succeed the factory, and I’m not going to in the future. In the first place, I left home saying “I’m going into the music world” (laughs.) Now I’m working as a designer, thanks to many people and connections.

Keiji (father): I wanted him to succeed the business if the industry was growing, but unfortunately the knitting industry has not been growing recently. I have had hard times running this factory, so I wasn’t very eager to have him succeed the business either.

Hiroyuki: I knew nothing about knitted products when I decided to start CHOOSE KNIT. I couldn’t even tell knitting from weaving.

Hiroyuki aimed to be a musician since he met guitar at 15. While experiencing various jobs, he taught himself how to desgin.

――Were you surprised to hear your son suggest starting a business together?”

Keiji (father): Actually I wasn’t. He kept asking about our factory’s situation before he brought up the idea… (laughs.)

Hiroyuki: I actually always wanted to create something with his factory. At my office, I usually help apparel makers and brands. Many times I felt jealous of them as I think it is very important to create something from scratch. Then I realized, “My family runs a factory!” Also, I always had this belief that more attention should be paid to factories as factories are making great efforts. However, when I consulted my father about this, he wasn’t very into it. He said it’s not so easy to start a new business.

Keiji (father): That was one thing, but also we didn’t know how an apparel business worked, which was necessary if we wanted to sell our products directly to the customers. But at the same time, I thought it’s not good to only keep doing the same thing. I knew I had to adopt new things. I hope CHOOSE KNIT can be the trigger for us to lead to a new phase.

Since 53 years ago, Oshima Meriyasu has been challenging to develop their own technique, such as pleated-knit (patented). Many ladies ware designers have long working with Oshima Meriyasu.

Until recently, Oshima Meriyasu kept their knitting pattern with floppy disks.

Keiji likes to move his hands; artistic objects that can be found inside the factory are made by him.

Hiroyuki: At first I wanted to make knitted clothes. We even made samples, but it turned out to be a failure. We didn’t have clothes designers in our team.

My father always says, “Products made in factories are designers’ products, not ours.” The factory is just to support the designers’ creation of the products in the manufacturing process.

Keiji (father): Yes, we don’t create anything from scratch. We usually combine the designers’ ideas and our techniques to create new things. At that time, I said to him that we should focus on items of which we could prepare enough variations, and we shouldn’t expand the range of products without giving it much thought.

Hiroyuki: I truly understood what he was saying after I tried clothes. We cannot design clothes like brands, but brands cannot make clothes without using certain techniques. Both are necessary to create clothes. Therefore, I decided to make high quality and simple choices for CHOOSE KNIT so that customers can choose materials like designers. We cooperate with the customers to complete the work.

――That’s why you adopted a customizing process involving customers?

Hiroyuki: Yes. Another reason is that I wanted to adopt the most complicated processes that factories would hate to do. I thought we can make our business unique and valuable by going against what is considered “normal” for factories: manufacturing the same products on a large scale. However, we cannot expand our business with completely tailor-made items. So I thought, if we have several “formats” that customers can follow, they can still decide on the designs themselves. I asked my father if we could do that, and he answered that he couldn’t say it was impossible.

Keiji (father): I said we can make simple stuff like scarves and blankets, as I cannot keep one machine only for CHOOSE KNIT products all the time. Making products to order is completely different from mass production. I wasn’t sure if we could do it, but I wanted to give it a try.

――You could have dealt with ready-made products with basic lineups…

Hiroyuki: Even now I think about it! It’s an easier way to convey our idea.

Keiji (father): I agree, but one of CHOOSE KNIT‘’s attractions is that we have many analogue processes. We should retain this feature.

Hiroyuki: Also, customers can communicate with their family, friends and partners in the designing process, which makes the products special to each customer.

Order book for kids’ are in picture book style. Kids paste stickers along the story to order. It was designed to create communication between parents and kids.

――I get the impression that both of you cooperate with each other to generate ideas. Do you think working with your father or son makes business easier?

Keiji (father): There are good and bad sides. I sometimes want to tell him off, but at the same time I think I stick to conventional ways of doing things, as I have worked in this industry for a long time.

Hiroyuki: I usually say “Let’s give it a try first”, and he says “Trying everything is not clever.” Sometimes we get stuck because of this argument. And, you got angry when I said, “Sometimes China makes better things than Japan,” didn’t you?

Keiji (father): We have pride. China went into this industry after us.

Staff for sewing samples has consummated techniques, “She has very long experience that she even could finish it faster than actual production. She is too fast that sometimes we even miscalculate quotes… (laughs)” says Keiji.

――It seems nice to be able to give your frank opinion to each other about your business. You cannot behave like that with your clients. By the way, any factories is facing problem of lacking successors. How about Oshima Meriyasu?

Hiroyuki: In my opinion, knitted products are the weakest “Made in Japan” products. Knitting techniques were imported from the UK and Australia. As they didn’t originate in Japan, knitters have a short history here of less than 100 years. It is very unlike traditional woven cloth, which has a long history and many factories. Knitting in Japan cannot be classified as a traditional craft.

Keiji (father): Because originally Japan has a kimono culture. I have been barely able to continue this business, as we have many unique techniques. My factory has been attempting to do something that others don’t do.

Some knitters have had their sons succeed their business, but most of them have reached their last generation. In the old days, people from apparel companies used to stay at factories for a couple of days, discussing the best ideas. But now times have changed.

Hiroyuki: If manufacturing becomes the trend, the number of successors would increase. But in my opinion there are industries that cannot avoid disappearing.

I started CHOOSE KNIT because I respect my father and other artisans who were working with him. I just wanted to find a way for his factory to survive. So, I didn’t start the business in the context of preserving the industry.

My cousins are working in the factory now. I want the factory to survive until they become managers, so we must sell many more products than we do now so that people start to think that working in factories is a good option.

Keiji (father): Yeah, we have to make a profit. Staff members would also be pleased and encouraged to see their products selling well. I hope CHOOSE KNIT will become more popular.

(Translation by Akiko ISHIGE)