In Japanese, the terms for skin/hide and leather are identical in pronunciation; they are both pronounced “kawa.” It may be easier in English to understand the difference between the two “kawas.”

Skin or hide is the name for the raw form. Being left raw, it will soon dry up and stiffen or get rotten. Leather stands for the processed—tanned—form. After tanning, the leather is less susceptible to decomposition, and now it can be used as a material for accessories and shoes.

Tanning is the process of treating the skins of animals to produce leather, by altering the protein structure of the skin. Tanning can be performed with either vegetable or chemical methods, these are commonly called ‘vegetable tanned’ or ‘chrome tanned.’

The chrome tanning method has become popular along with economic growth. On the other hand, factories that can handle vegetable tanning are getting less and less. Due to recent studies that point out the negative impact to the environment and human body of chrome tanning, more and more people are becoming aware of the advantages of vegetable tanning. However, it may be too late to make changes.

Visiting a Vegetable Tanning Factory “Tochigi Leather”

In Tochigi prefecture, which is located in the Northern Kantō region, there is a tannery that is treating leather using traditional methods, while respecting the environment. I attended the open-factory event in December 2013.

You can walk to Tochigi Leather from Tochigi station. At the event, we were guided step-by-step in how skins are turned into leather.

First of all, we went into the warehouse where salt-soaked raw hides are kept. Meat and fur is still stuck at this point, and the room was filled with the smell of animals. It would smell more in the summer. The scene and smell strongly reminded me again that leather is a material from animals.

The hides are washed with water first to remove salt, dust, and dirt. The raw hide is cut into half after washing, because it is too large to be handled in the later procedures.

After soaking, the soaked hides and skins are taken for the next process where they are treated with milk of lime. It is mainly to remove the fur, nails, and other keratinous matter, some of the interfibrillary soluble proteins like mucins, and the natural grease and fats to some extent. The fur falls off naturally as the skin is softened. The ground was white with fallen fur.

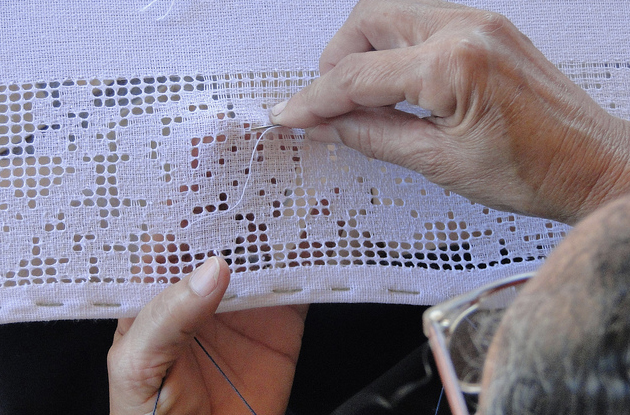

Then we moved on to see a procedure called “fleshing.” This is a continuation of the scraping or fleshing that was done by hand after flaying. Then, it is “delimed,” meaning partially neutralized since skins become strongly alkaline during liming. Afterwards, the skins are left in the bath and ‘bated,’ which gives them the required degree of softness, pliability, and elasticity. All the preparation methods take several days. Finally, they are prepared for tanning.

Seeing How Skin Transforms into Leather

We are now able to start tanning. Inside the building, there were rows and rows of acid baths, which each contained different concentrations of auburn acids. This auburn acid is the tannin, a vegetable extract obtained from different part of plants including woods, barks, fruits, fruit pods, and leaves. At Tochigi Leather, they mainly used Brazilian mimosa.

The skins and hides go through the acid bath one by one. During the bathing, the proteins on the skin transform and the skin turns into leather. After several days of soaking, the leather is washed, and dried completely in a machine called a summing machine.

Tanning Procedures. Acid bath in a row(IMAGE: ami-tsumuli)

After finishing by adding oil, flattening equally, coloring, now we have the leather that we are familiar with. At this point, we can easily imagine how this material turns into daily goods, such as belts, shoes, and bags. You can sense no “animal” by now.

Let’s Care More about Procedure as Well as the Consequence

I have noticed that tanning procedures use a lot of water. At Tochigi Leather, they have their own drainage system, where they treat water from each procedure with only bacteria and minerals. They say they do not need any chemical acids to achieve effluent standards. What is more, they offer farms their sewage as an organic fertilizer.

They are not sure why they are capable of this organic method, because there are too many “miracles” going on. However, one reason is that they do not use any metallic acids. The president of Tochigi Leather told me that it would have been impossible to achieve this organic drainage method if they had been using chromium for tanning, instead of mimosa.

仕上がったヌメ革。(IMAGE: ami-tsumuli)

Shoes, bag, wallets, sofa, jacket… our life is filled with leather products. Tanning procedures differ according to the types of skin. However, with each method, it may be consuming tons of water and chemical acids. Of course, there should be effluent standards in each country, but I am not sure how each standard is fixed and observed.

Using bi-product skins could be logical and efficient, and it can be said to be “ethical”. However, we need to look further than just that. We need to turn skin into leather, and there is another environmental burden to do so. At the same time, we need to encourage the methods that minimize the impact on the environment.